MULTI LAYER CERAMIC CAPACITORS (MLCC) DICING

Green ceramic, a basic capacitor consists of two conducting electrodes separated by an insulating dielectric material. Multi-layer ceramic capacitors consist of a large number of closely spaced parallel electrodes between thin layers of a high-capacitance ceramic material.

Major MLCC Dicing Considerations:

- Nuisance dust in ‘dry’ dicing operations

- Blade clogging

- Layer smearing and shorting

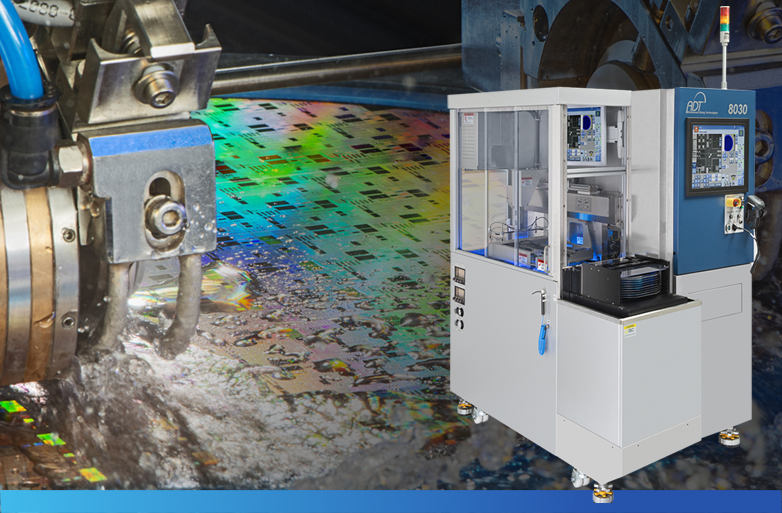

Dicing Saw:

7124 dicing saw, high level of automation, large blade size for better Cost -of -Ownership

Dicing Blade:

- 4″ Nickel (standard or serrated edge) and steel core Nickel Blades

- OD Ø: 2”, 3″, 4″

- Diamond grit size: 30 – 70 µm

- Thickness: .006″ – .014” (0.15 – 0.35 mm)

Dicing Process Parameters:

- Feed rate: 50 – 250 mm/sec

- Spindle speed: 12 –30 krpm

- Possible for both ‘dry’ and ‘wet’ dicing

- Relatively frequent dressing to clean the dicing blade from debris