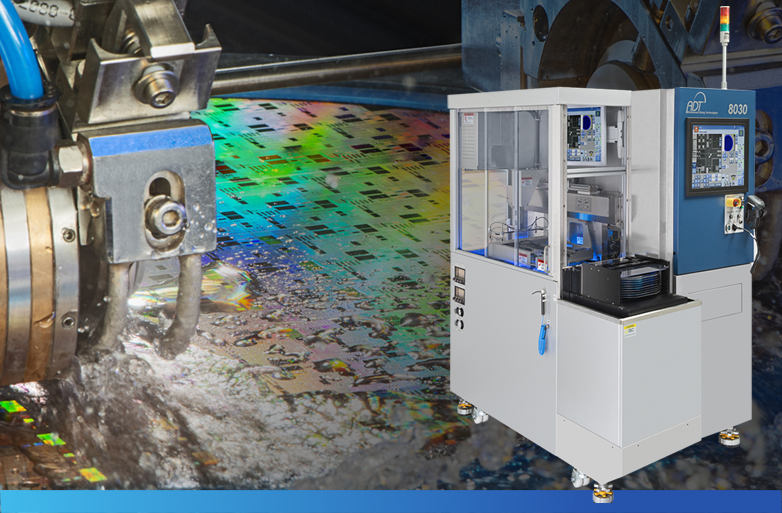

Resin BOND DICING Blades

- DICING BLADES

- > RESIN BOND BLADES

FEATURES

RESIN BINDER

Resin binder enables blade wear management.

DICING APPLICATIONS

Resin-Bond Dicing Blades are an excellent choice for hard and brittle materials such as: QFN, Thick Ceramic Substrates, LTCC and Glass,

Wettable QFN

Wettable QFN

DICING BLADE THICKNESS

From 75 µm to 2500 µm

DIAMOND GRIT SIZE

From 3 µm to 250 µm

Tailored Diamond Dicing Blades

We offer precision-engineered diamond blades customized to meet the exact specifications of your dicing application, ensuring optimal performance and consistent results.

| Diamond grit size (µ) | Product | Material | Matrix |

|---|---|---|---|

| 35 up to 53 | Ceramic Packages, Sensors | Alumina / AlN | C02/C07 |

| 53 up to 88 | QFN (Half Etched Cu) + Wettable QFN (full cut) | Cu leadframe + molding | D02/D07 |

| 53 up to 88 | QFN (Full Cu) | Cu leadframe + molding | E01 |

| 35 up to 53 | DFN (0.3-0.5mm) | Cu leadframe + molding | E31/D02 |

| 53 up to 88 | Wettable QFN First cut | Cu leadframe + molding | P07 |

| 30 up to 45 | SAW Devices, RF Package | HTCC | QKP/C02 |

| 30 up to 53 | CCD / Filter / Lens | Glass / Quartz | QKP/E33 |

| 45 up to 63 | Optical & Electro Optical Components | Sapphire | QKP |

| 30 up to 53 | Passive & Active Devices. Communication Modules | LTCC | QKP |

RESIN-BOND DICING BLADES PART NUMBER DESCRIPTION