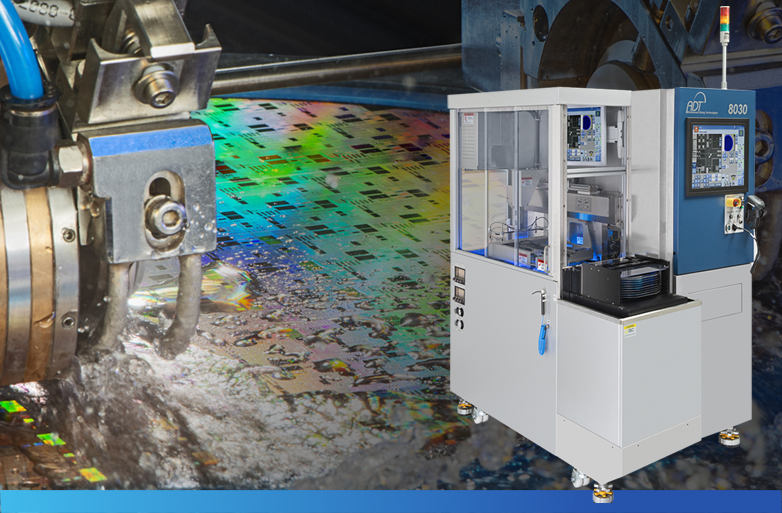

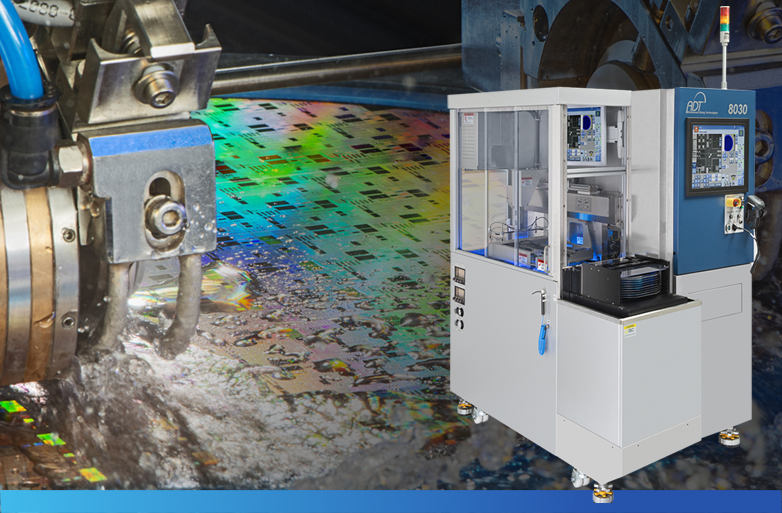

8030 – Fully Automatic Twin Spindle Dicing Saw

8030 - High end fully automatic twin spindle saw, packed with features and benefits. Up to 12”...

Read more >

Loading up to 4 QFN magazines, Each with up to 20 QFN substrates

Double spindle

Optional:

Automatic loading 2 QFN panels (can support single panel)

For the 2 substrates simultaneously

RELATED DOCUMENTS

Feed Rate: 50 mm/sec

Mapping Feed Rate: 50 mm/sec

Mapping Rate: 5 Cuts

Brush Cycles: 1 Feed Rate

During Brush: 10 mm/sec

Since cleaning is done during dicing the cleaning time does not effect the total processing time

| Specifications | 80WT | |

| Workpiece Size | up to12" by 12" Square | |

| Spindle | 1.8 KW Two facing spindles | |

| LMS (Laser Mapping System) | Accuracy | ±15 μm |

| Blade Size | 2" - 3" | |

| Y1 / Y2 Axis | Control Resolution Cumulative Accuracy Indexing Accuracy Cutting Range | Linear encoder for each Y axis 0.1 µm 1.5 µm 1.0 µm 350 mm |

| X Axis | Air Slide | |

| Z1 / Z2 Axis | Resolution Repeatability Max. stroke | 0.2 µm 1.0 µm 50 mm (for 2.188” blade OD) |

| Θ Axis | Repeatability Stroke | 4 arc-sec 380° |

| Cleaning Station | Spinning speed Cleaning method | Full rinse and dry cycle 100-3,000 rpm Atomized cleaning capabilities |

| Utilities | Electrical | 200-240 VAC, 50/60 Hz, single phase |

| Dimensions | (W x D x H) mm Weight | 1145 × 1687 × 1830 mm 1,500kg |

Copyright © ADT – Advanced Dicing Technologies, 2025

ADT – a leading developer & global supplier of high-performance Dicing Solutions, including Dicing Saws, Dicing Blades, Dicing Peripherals, and a complete range of Accessories — engineered for precision, built for excellence.

Design Maxmark