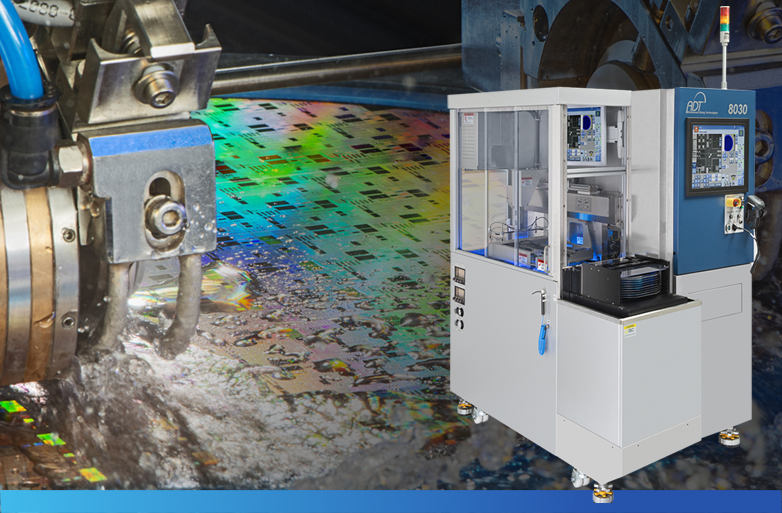

INNOVATIVE DICING BLADES

DICING BLADES RANGE

DICING BLADE SELECTION

Choosing the right blade to suit your application is crucial to the success of your dicing process. ADT’s dicing blade selection is comprised of three product families distinguished by bonding material: resin-bond blades, nickel-bond blades and metal-bond (sintered) blades.

DIAMOND DICING BLADES TECHNICAL INFORMATION

Blade

Selection

Selection

Process

Parameters

Parameters

Dressing

Lot

Identification

System

Identification

System

Tailoring

Dicing

Solutions

Dicing

Solutions

DICING PROCESS – HANDLING TIPS

- When you have a choice, be sure to pick the appropriate type of spindle for your application (2”, 4”)

- When mounting on tape, always make sure that the substrates are mounted properly to avoid air bubbles and non-uniform tape tension

- When using a non-tape-based mounting method, make sure that the substrate is held securely to eliminate any die movement during the dicing process

- Ensure no damage to the flange (nicks, scratches) to avoid dicing blade breakage and oversize cut widths

- As a starting point, follow the dicing blade exposure rule of thumb regarding maximum recommended ratio of blade exposure to thickness:

- Resin-blades 10:1

- Metal Sintered Blades 20:1

- Nickel Blades 30:1

- Double check your cutting parameters before you begin dicing (e.g. dicing blade type and P/N, spindle speed, feed rate, cut depth, water flow rate, cooling pressure)

- Always handle the blade with special care when transferring it from the blade package to the flange and to the spindle

- Make sure that the dicing blade is properly mounted in the flange and that the flange is properly mounted to spindle. Be sure to use a torque meter for controlling the amount of closure sensitive applications

- Make sure that the blade and the substrate are cooled sufficiently by adjusting the coolant nozzle and the flow rate

- Consider dressing and override procedures in order to prepare the blade for the cutting process

- Consider periodic dressing during dicing in order to maintain the quality of the blade edge