技術新知

QFN/MLP封裝

2012年10月30日

QFN/MLP基板的行為與微電子產業中大多數已知材料的行為有很大不同,因此對切割工藝提出了挑戰。本文將涵蓋基本的基板特性和各種單一化主題。

MEMS切割

82006年8月8日

Dr. Ramon J. Albalak

微電子機械系統(MEMS)包括多種微型化智能機械系統,例如加速度計、流量傳感器、運動鏡和射頻設備。MEMS是通過集成電路(IC)製造技術與各種微加工工藝相結合來製造的,這些工藝可以選擇性地蝕刻掉矽晶圓上所需的部分,或創建額外的層……

封裝單一化過程

2006年7月31日

Dr. Ramon J. Albalak

越來越多的矩陣封裝形式和複雜性給許多後端工藝帶來了真正的挑戰。將這些陣列分離為單獨的封裝是製造過程中的重要一步,並且在許多情況下,需要優化以將封裝的總成本降到最低。

封裝分割工藝

2006年7月31日

Dr. Ramon J. Albalak

對於許多後端製程來說,這是一個挑戰。將這些陣列分割成單個封裝是製造過程中的一個重要步驟,如同在許多情況下,需要對其進行優化,以最大限度地降低封裝的總成本。

複雜晶圓中包含低介電材料、銅和 TEGs 街區的分割工藝中的質量與可靠性考量

2006年7月31日

Dr. Ramon J. Albalak

本文介紹了一種用於分割包含低介電材料、銅和街區 TEGs 的複雜晶圓的工藝。該方法基於一種新的刻劃工藝,使用二氧化碳雷射移除一層非矽元素的薄頂層,隨後進行機械切割,完全切穿晶圓的剩餘厚度。

本文討論了雷射刻劃對切割質量和晶粒強度的影響,並與傳統的兩步切割工藝進行比較。

切割聲表面波裝置

2006年7月12日

Dr. Ramon J. Albalak

聲表面波(SAW)裝置是利用壓電材料將聲波(即機械波)轉換為電磁信號,反之亦然的元件。迄今為止,最常見的 SAW 裝置是 SAW 帶通濾波器(SAW BPF),它通過頻率來篩選信號,並廣泛應用於有線和無線設備中,包括手機、有線電視設備、無線電話和傳呼機等。

聲表面波裝置

2006年7月12日

Dr. Ramon J. Albalak

聲表面波(SAW)裝置是一種利用壓電材料將聲波(即機械波)轉換為電磁信號,反之亦然的元件。最常見的 SAW 裝置是 SAW 帶通濾波器(SAW BPF),它可以通過頻率篩選信號,並廣泛應用於各種有線和無線設備中,包括手機、有線電視設備、無線電話和傳呼機等。

微電子行業中對硬脆材料的切割 2005年12月1日

2005年12月1日

Gideon Levinson

大量的微電子切割應用需要完全切穿基板。雖然部分切割相對容易,但切割硬脆材料會帶來安裝和質量問題。本文討論了與切割過程相關的各種安裝技術和質量問題,並提供了解決這些問題的建議。

微電子基板切割工藝的優化

2005年10月20日

Gideon Levinson

微電子行業不斷尋求在各種複雜的切割應用中提高產量。為了改善切割質量和產能,持續進行努力。引入了一些需要新工藝(刀片和鋸片)的新材料。這些趨勢伴隨著持續縮小晶粒尺寸的努力,以最大化每片基板上的晶粒數量。為實現這些目標,優化切割工藝是必須的。

通訊市場中的光電元件切割

2004年12月1日

Gideon Levinson

通訊市場提供了種類繁多的光電元件。該市場仍處於成長階段,許多新創公司引入了新的基板設計,並帶來了新的切割挑戰。近年來,使用與超大規模集成電路(VLSI)兼容的技術和其他成熟技術(如微機電系統 MEMS)開發了新一類的集成和可調光學元件。

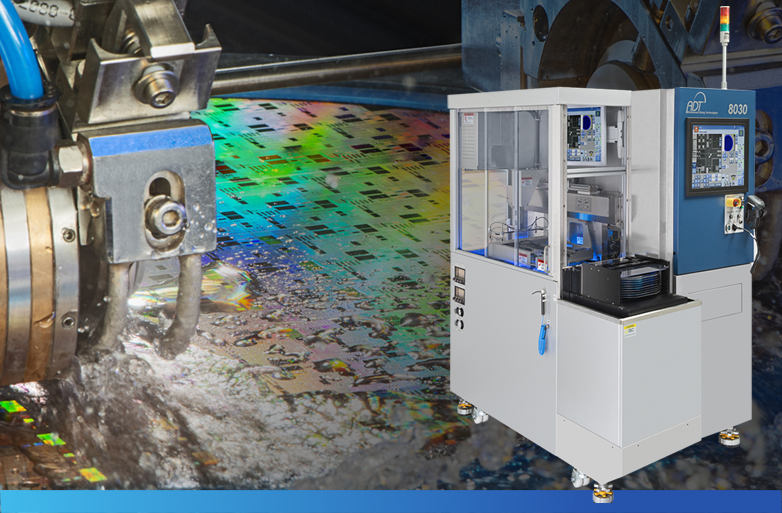

切割原理

2004年2月1日

Gideon Levinson

切割(或鑽石砂輪鋸切)在微電子行業中用於晶片分離,也用於精細、準確的部分切割以及對特殊、非常硬且脆的材料進行完全切割。由於加工的材料範圍廣泛,因此需要使用不同的刀片。這些刀片可能基於硬或軟的粘結劑,並具有各種尺寸的鑽石顆粒。

MLF/QFN 基板分割的考量

2003年7月12日

Gideon Levinson

MLP/QFN 基板的切割行為與微電子行業中大多數已知材料非常不同。本文將討論材料結構和行為、行業追求的質量標準、優化切割工藝的基板設計要求以及切割工藝中涉及的參數。特別是,本文將探討現有的刀片選項,並指出改進和優化的機會。